Did you know? Winter road salt can cause untreated garage floors to deteriorate up to 25% faster each year—threatening your home’s value and leading to costly repairs. If you park your car in the garage after a snowy day, those slick road salts can wreak havoc on your concrete, eating away at its surface and underlying strength. In this comprehensive guide, you’ll discover all you need to know about preventing salt corrosion on garage floors and keeping your home’s foundation strong, clean, and safe for years to come.

Startling Facts: The True Impact of Salt Damage on Garage Floors

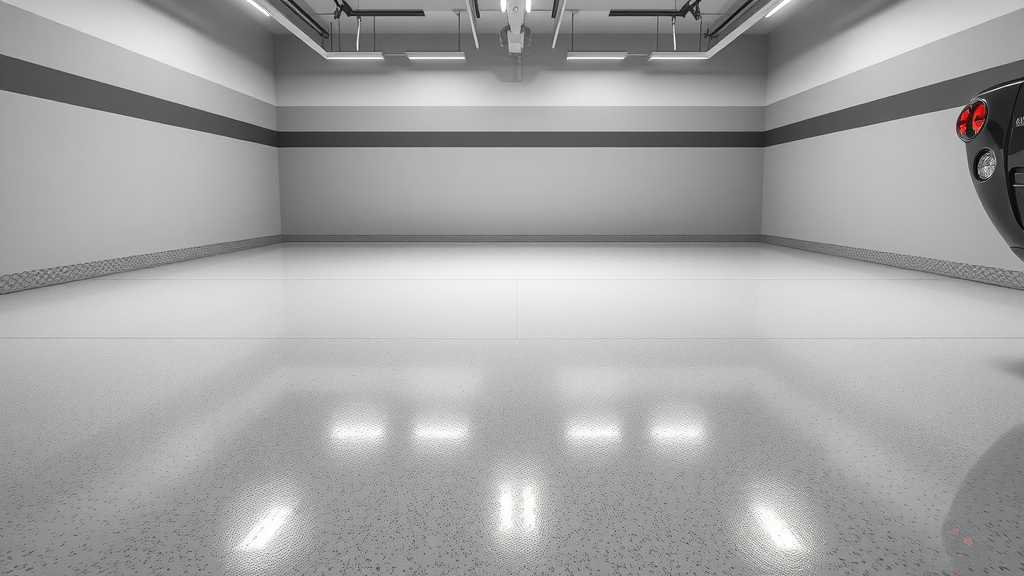

Salt damage isn’t just a surface issue; it penetrates deep into your concrete garage floor, especially after the winter months when melted snow and road salt soak in. These effects of road salt can cause unsightly stains, crumbling, and even structural cracks. Studies indicate that a neglected garage floor exposed to these harsh deicing chemicals can suffer a significant loss in integrity, resulting in uneven surfaces that gather more moisture and accelerate the deterioration process. The good news is that modern floor coatings, such as epoxy coating and polyaspartic coatings, provide a protective barrier—but only if applied and maintained correctly. Addressing salt damage early and proactively is critical not only for the appearance of your garage but also for the safety and longevity of your home’s concrete foundation.

Salt corrosion is especially a concern for homeowners in colder climates or urban areas where municipalities use heavy amounts of road salt. When vehicles enter the garage, this road salt gets deposited, and repeated freeze-thaw cycles during winter months feed the process, widening cracks and allowing more water and salt to bypass into the concrete matrix. Over time, this repeated exposure can outpace natural drying cycles, leaving even a seemingly healthy garage floor at risk. Those with coated garage floors can reduce these effects immensely, while unprotected or damaged concrete is especially vulnerable. Prevention and regular maintenance are key to stopping the cycle of damage caused by relentless road salt exposure.

“Studies show untreated garage floors exposed to winter road salt can deteriorate up to 25% faster each year.”

What You’ll Learn About Preventing Salt Corrosion on Garage Floors

- The science behind salt corrosion on concrete garage floors

- How road salt damages garage flooring and coatings

- Best strategies, from cleaning to epoxy and polyaspartic coating

- Pro tips for long-term garage floor preservation

Understanding Salt Damage and Corrosion in Concrete Garage Floors

At its core, salt corrosion of concrete garage floors stems from the chemical interaction between road deicers (mainly sodium chloride, but also other salts) and the concrete matrix. Concrete is a porous material, meaning it naturally absorbs water. When this water contains salt, the dissolved ions are drawn into the concrete, slowly breaking down its internal structure. Essentially, as salt-laden water seeps into tiny cracks, it disrupts the concrete’s alignment at a molecular level, compromising both strength and appearance. This is especially problematic for those with older, unsealed, or already damaged garage flooring, because surface imperfections create even more entry points for salt and moisture.

Not only does this process threaten the visible integrity of your garage floor from salt stains and pitting, but it also raises the risk of more costly repairs if left unchecked. Over time, the trapped salts react with the reinforcing steel embedded in the concrete, accelerating rust and creating significant pressure that can lead to spalling (a chipping or flaking of surface concrete). Even those with coated garage floors may overlook small breaches in the sealer, which can become unseen channels for salt water. That’s why understanding the science behind garage floor salt damage is essential for every homeowner who wants to protect their garage floor from salt all year round.

Why Road Salt Harms Garage Flooring

The main reason road salt harms garage flooring is its ability to break down and penetrate concrete’s porous network. As vehicles bring road salt into the garage, it mixes with melted snow and water and is quickly absorbed into the surface. This salty moisture doesn’t simply evaporate—it works into the concrete and can remain for months, weakening bonds between aggregate and cement. The result isn’t just aesthetic salt stains but deeper chemical reactions that directly undermine the durability of your garage floor.

Furthermore, when the weather fluctuates, freeze-thaw cycles force trapped salty water to expand and contract inside the concrete. This ongoing stress causes microcracks, which grow more pronounced over time. Since garage floors often double as workspaces and storage areas, unchecked salt damage can lead to hazardous, uneven surfaces. Even advanced epoxy coatings, if not properly maintained, can eventually be breached by persistent salt intrusion. In summary, preventing salt damage is not only about preserving curb appeal but also about safeguarding your overall home investment.

How Salt Damage Weakens Your Concrete Garage Floor Over Time

Salt damage isn’t an overnight process—it builds gradually but relentlessly with each winter season. As more road salt accumulates, so does the degree of chemical attack inside the concrete garage floor. Over several years, you might notice your once-smooth floor has begun to feel rough, show white efflorescence, and display cracks. This is because the constant presence of road salt accelerates the breakdown of the concrete’s binding agents and increases the risk of moisture getting deeper into the slab itself.

During warmer periods, even if no new salt is tracked in, previous accumulations remain active within the concrete matrix, keeping the corrosion process going year-round. Small cracks eventually expand, enabling even greater infiltration during subsequent freeze-thaw cycles. As a result, the structure of the garage floor weakens, potentially threatening anything stored above it. For those considering high-quality epoxy coatings or polyaspartic coatings, it’s crucial to address these underlying issues before application to ensure your chosen protective barrier can fully cure and provide long-term defense.

“Salt isn’t just a winter problem—its effects can linger year-round within the concrete.”

Key Causes of Road Salt Corrosion in Garage Floors

- Freeze-thaw cycles and moisture

- Road salt chemical composition

- Water infiltration in unprotected garage floors

Freeze-thaw cycles are notorious for expanding water trapped inside concrete garage floors. As water repeatedly freezes and expands, then thaws and contracts, it exacerbates tiny cracks that allow salt deeper into the concrete matrix. Combined with the abrasive chemical reactions from common deicing agents, even a single winter can have lasting effects. Because most garage floors are unheated, the fluctuations between warm vehicle tires and winter air intensify these cycles, speeding up damage.

The specific composition of road salt (such as calcium chloride and magnesium chloride) affects not only how quickly the salt melts ice but also how aggressively it attacks your concrete. These types of salt are highly soluble and able to penetrate even the smallest pores. Add to this the challenge of water infiltration—especially on unsealed or cracked garage floors—and you have a recipe for ongoing corrosion, spalling, and inevitable repairs unless preventative measures are taken quickly and effectively.

Top Methods for Preventing Salt Corrosion on Garage Floors

Regular Cleaning and Salt Removal Techniques

The foundational step in preventing salt corrosion on garage floors is consistent and thorough cleaning during winter months and beyond. Start by routinely sweeping away loose debris and salt crystals before they can dissolve in melted snow. Use a stiff-bristled broom and a wet mop, then rinse with clean water to remove as much salt as possible. For stubborn residue, a neutralizing cleaner designed specifically for road salt can break down the alkali effects, stopping salt from settling into your concrete and causing further harm.

It’s important to never let pools of salty water linger on your garage flooring. Immediate removal significantly reduces the risk of damage, especially on high-traffic areas where salt is most concentrated. For added defense, consider placing mats or trays at the garage entrance to absorb excess water and collect salt before it touches the concrete. Remember, regular cleaning not only protects against current salt exposure but also makes the next round of cleaning more effective—helping maintain a healthy, attractive garage floor all season.

Choosing the Right Floor Coating: Epoxy Coating and Polyaspartic Coating

One of the most robust ways to shield your garage floor from salt is by applying a high-quality floor coating. Epoxy coatings and polyaspartic coatings offer superior protection by forming an impermeable layer that resists water, chemicals, and abrasion. An epoxy coating is known for its toughness, glossy finish, and the ability to bond well with concrete. Polyaspartic coatings, however, take durability a step further by providing even stronger chemical resistance, faster curing times, and superior performance in extreme temperatures.

When selecting a coating, consider your climate, maintenance schedule, and desired look for your garage flooring. Both options are designed to prevent moisture and salt from ever reaching the garage floor’s porous matrix. However, polyaspartic coatings tend to be more flexible and long-lasting, making them the best choice for garages facing heavy road salt exposure. No matter which product you select, professional installation ensures an even, long-lasting barrier, protecting your investment for many winter seasons to come.

DIY vs. Hiring a Pro: Protecting Your Garage Floor from Salt Damage

Protecting your garage floor from salt can be a DIY project, but there are significant benefits to hiring a professional. DIY kits from home improvement stores might seem cost-effective and straightforward, yet results often vary due to inadequate surface preparation or improper product application. Gaps, bubbles, or thin spots in an amateur epoxy coating may leave your garage flooring vulnerable, especially in harsh winter months.

On the other hand, when you hire a pro, you benefit from industrial-grade coatings, advanced preparation equipment, and expert installation experience. Professionals will ensure that the floor is perfectly clean, that all cracks and salt-damaged concrete are properly repaired, and that the coating is applied evenly for complete protection. They’ll also advise whether an epoxy or polyaspartic coating is better for your needs. While professional services may cost more upfront, they extend the life of your coated garage floor and decrease the risk of costly repairs down the line.

Comparing Popular Epoxy Coatings and Polyaspartic Coatings for Garage Flooring

| Floor Coating Type | Durability | Salt Resistance | Application Time | Cost |

|---|---|---|---|---|

| Epoxy Coating | High | Good | Long | $$ |

| Polyaspartic Coating | Very High | Excellent | Short | $$$ |

Detailed Guide: Step-by-Step Process for Preventing Salt Corrosion on Garage Floors

- Sweep and wash away loose salt

- Use a neutralizing cleaner for road salt residue

- Inspect for signs of salt damage or efflorescence

- Apply an appropriate floor coating (epoxy or polyaspartic)

- Regularly maintain coated garage floors

Begin by removing all vehicles and storage items so you can address the entire surface. Sweeping up loose debris and salt ensures you don’t push it deeper into the concrete during cleaning. Next, apply a neutralizing cleaner to dissolve the remaining salt film. Look closely at the concrete for any powdery or chalky white spots (efflorescence) or visible cracks—these are early signs of salt and water damage. Once the slab is dry and fully inspected, apply the floor coating according to the manufacturer’s directions. If you choose an epoxy or polyaspartic product, ensure proper curing by waiting the full recommended time before driving or placing objects on the floor. Finally, maintain your newly protected surface by sweeping and washing regularly, and addressing spills or standing water immediately.

Watch as an expert demonstrates the step-by-step process—from salt removal to coating application—with clear before/after visuals and guidance for any skill level.

People Also Ask: How do I protect my garage floor from salt?

Answer: Protecting your garage floor from salt involves cleaning regularly to remove road salt, applying durable coatings such as epoxy or polyaspartic coating, and quickly addressing any damage. Using mats or sealants can also help minimize salt exposure.

People Also Ask: How to prevent efflorescence on garage floor?

Answer: To prevent efflorescence, ensure high-quality sealants or floor coatings are applied to the concrete garage floor. Address moisture issues and maintain consistent cleaning to reduce salt and water infiltration.

People Also Ask: How to stop salt corrosion on concrete?

Answer: Stopping salt corrosion on concrete requires both removing salt promptly and applying protective floor coatings. Regular inspections and timely repairs of small cracks also prevent further salt infiltration.

People Also Ask: How to neutralize road salt on garage floor?

Answer: Neutralize road salt by using commercial salt neutralizers or a mixture of water and vinegar. Always rinse thoroughly and dry the area to prevent moisture-related salt damage.

Essential Maintenance Tips for Preventing Salt Corrosion on Garage Floors

- Regularly sweep and wash your garage floor

- Use mats or trays to trap salt before it contacts the concrete

- Apply a fresh coat of floor sealer or coating every few years

Maintenance remains the single most important step in preventing salt corrosion on garage floors. Sweeping and washing low-traffic and high-traffic areas alike prevents salt from accumulating and soaking into the surface. Entryway mats or catch-trays absorb water and salt before it spreads and dries on the concrete. For ultimate long-term protection, a fresh application of sealer or floor coating every two to five years (depending on your environment and usage) will ensure your garage floor remains resistant to both salt and moisture infiltration. This proactive approach not only preserves the look of your concrete garage but also strengthens its performance season after season.

Key Takeaways: Preventing Salt Corrosion on Garage Floors

- Preventing salt corrosion on garage floors requires proactive maintenance and high-quality coatings

- Epoxy and polyaspartic floor coatings offer the strongest barriers against salt damage

- Immediate action against salt and moisture buildup is essential

FAQs: Common Questions on Garage Floor Salt Damage and Prevention

-

How often should I reseal my concrete garage floor for salt protection?

It's best to reseal every 2 to 3 years, or sooner if you notice spills, stains, or surface dullness. High-traffic garages exposed to frequent road salt may need more frequent attention to remain protected. -

Can salt damage already coated garage floors?

Yes, if the coating becomes scratched, worn, or cracked, salt water can still find its way inside. Regular inspections and quick spot repairs extend the life of your coated garage floor. -

Is DIY epoxy coating as effective as professional installation?

DIY kits can work for minor updates, but professionally installed coatings offer stronger adhesion, more even coverage, and higher resistance to salt and chemicals. Hiring a pro is recommended for long-term durability.

Conclusion: Take Control with Preventing Salt Corrosion on Garage Floors

Take these steps today to guard your garage floor from salt damage—protect your investment, keep your home safer, and avoid expensive repairs.

“A small investment in garage floor protection today can save thousands in costly repairs tomorrow.”

Call to Action: Call Us Now to Get Your FREE Quote! 800-280-9210

Ready to protect your garage floor? Call us now at 800-280-9210 to schedule your FREE quote and get expert help in preventing salt corrosion on garage floors!

To further enhance your understanding of preventing salt corrosion on garage floors, consider exploring the following resources:

This guide delves into the causes and effects of salt damage, offering detailed steps for cleaning, repairing, and protecting your garage floor from future salt exposure.

This article provides a comprehensive approach to removing salt stains, repairing winter damage, and implementing preventive measures to safeguard your garage floor against salt-related deterioration.

By consulting these resources, you’ll gain valuable insights and practical techniques to effectively protect your garage floor from the harmful effects of road salt.

Add Row

Add Row  Add

Add

Write A Comment